604-904-8614

United Boulevard Recycling and Waste Centre

IN Commercial Installation Projects, Community Installation Projects, Industrial Installation Projects

Investor Name:

Metro Vancouver

Published Date:

September 30, 2021

Location:

Coquitlam, BC

Value:

10,000,000+

Architecture:

Pre-fabricated steel structure and envelope

About Project

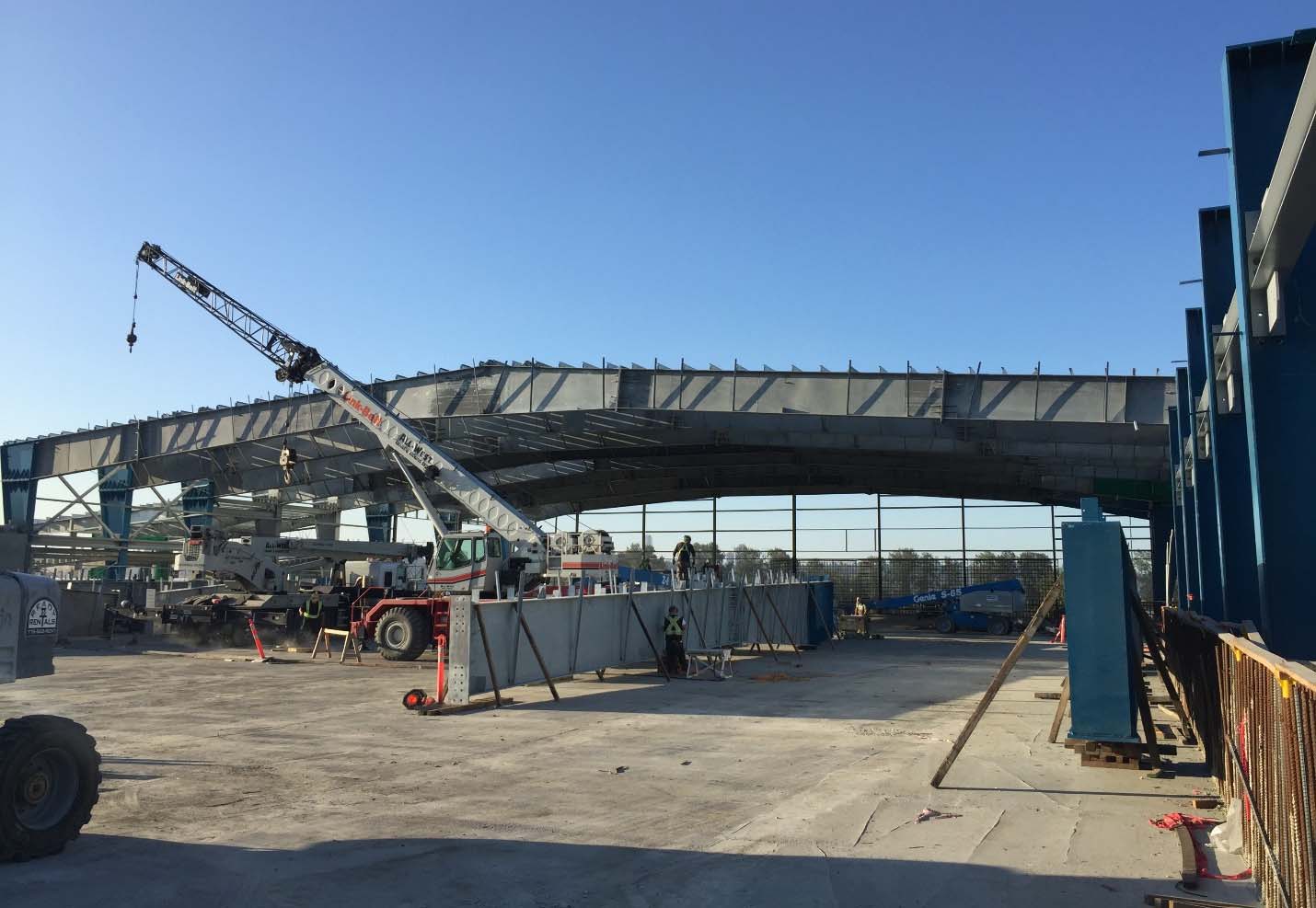

We recently have successfully completed a complex project located in Coquitlam, BC – United Boulevard Recycling and Waste Centre owned by Metro Vancouver. This new recycling and waste centre is on a 15.5 acre (6.2 Hectare) site and will serve the growing community and help reach our regional recycling goals of 80%. It will be a full-service waste and recycling facility serving commercial, residential, and small business customers. Residential and commercial vehicles will be segregated to improve traffic flows and safety. A large free recycling area is also included in the design. The facility will be open 363 days a year, serving about 200,000 customers.

We have supplied and installed the Pre-engineered Main Transfer Station Building (approx. 70,000 sqft), Scale House Canopy and Recycling Canopy. The buildings surpassed 10 million dollars in total contract value. Our engineer team worked closely and had multiple meetings with the owner’s consultants (structural engineers and architects) to assist and optimize the building structural design as well as building envelope. We endeavoured and have met the client’s needs and expectations safely on time and on budget. Our design team have generated a very useful IFC model for the client’s convenience and clash detections. This was especially helpful with identifying some challenging steel connections while we worked through our installation sequencing and multi crane lift planning. We conquered many engineering challenges such as poor soil class F, stringent differential settlement and 233’ clear span design with reverse tapered columns protruding the building envelope adding a complex architectural element to the design. This large clear span pushed the limits of Pre-engineered Metal Building capabilities. Many manufactures were unable to design and fabricate this project.

The foundation schedule delayed us, but we helped mitigate the additional delay cost and overall schedule loss by postponing procurement and changing our installation approach to preassemble large sections. This allowed us to commence with an abundance of ground level work assembling large sections together while we were waiting for forms to be stripped and concrete to cure. We implemented ongoing coordination with all trades at a site level and properly forward planned our overlapping scopes to achieve a common goal of working safely on time and on budget.